Farming activities cannot be operated without livestock barns, which act as essential facilities in this sector, but when the air quality is poor due to ammonia and odors, there is the possibility of both animal health, worker safety, and the profitability of this farm. The accumulation of ammonia, which is mainly due to the decomposition of manure, causes respiratory problems and low productivity, and the odor influences the adjacent communities and compliance with the legislation. HVLS ceiling fans, particularly the industrial ceiling fans, are very useful in curbing the development of ammonia in the barns as well as the control of odor build up in the barns by enhancing the circulation of air to dispersing the harmful gases in the air and ensuring that the air is healthier to the livestock and the workers. These fans offer quantifiable returns by reducing concentration of ammonia rates by 15-25 percent and reducing the costs of ventilation by 20-30 percent. Farmers and livestock managers can change the manner in which management of barns are conducted by understanding this. Having more than 20 years of experience regarding ventilation solutions, RTFANS has assisted farms in the enhancement of air quality. At this point, we can continue with the issues of ammonia and odors, health hazards, the role of fans, benefits, a case example, and frequently asked questions.

The Problem of Ammonia and Odors in Barns

The ammonia (NH3) and odor are prevalent in livestock barns, which are caused by daily activities, as well as, the lack of well-ventilated rooms.

Ammonia Comes from Urine and Manure Breakdown

According to the agricultural research, ammonia is produced when urea in urine decomposes releasing gases at the rates of 5-20 grams per cow per day. The concentration can rise higher than 25ppm in the ill-ventilated barns, which is the level at which the animals begin to feel uncomfortable. Manure Volatile compounds contribute to the problem through the odors that cause poor environments.

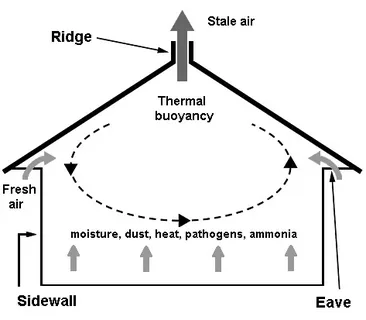

Poor Airflow Leads to High Concentrations

In the absence of proper ventilation, ammonia and odors will be trapped in stagnant air areas particularly inside large barns (10,000-50,000 square feet) that have high ceilings. Studies on livestock air quality show that this accumulation triggers eye irritation at 15-20 ppm, and respiratory damage at 25 or more ppm. Farms that experience low air flows are at a greater risk because the gases accumulate around the animals.

Health & Productivity Risks

Ammonia and odor can be very dangerous to animals, labor and processes.

Livestock: Respiratory Diseases and Reduced Productivity

Ammonia concentration of more than 10-15 ppm augments the onset of respiratory infections such as pneumonia in calves and pigs by 20-30% lowers milk production in dairy cows by 5-15% and weight gain in beef cattle by 10%. Poor air quality contributes to the higher mortality of poultry (5-10%). Odors are stressing factors to animals, which reduces the feed consumption by 5-10 percent, affecting the rates of growth.

Workers: Exposure Risk and Poor Working Environment

Employees working in an environment with ammonia over 25 ppm are at risk of irritation of their eyes and throats and may have chronic bronchitis as the long-term illness. OSHA establishes 50 ppm of PELs with 8-hour exposure, whereas on a case of barns that is not ventilated, the exposure is usually higher. Odors demoralize, causing a ten to fifteen percent turnover.

Compliance: Penalties for Exceeding Environmental Standards

The farms are liable to pay fines in cases where the ammonia emission surpasses the EPA limits (100 lbs/year reporting). Complaints about odors by neighbors would result in regulatory measures that would cost the company 5,000-20,000 to upgrade compliance.

How Ceiling Fans Help

The ceiling fans used have an HVLS diameter that ranges between 8-24 feet, with speeds as low as 400-800000 cubic feet per minute, thus providing specific solutions in reduce ammonia livestock housing.

Create Continuous Airflow That Disperses Ammonia Gases

The fans produce HVLS that cover a 10 000 22 000 square feet per unit, dilute ammonia by 15 percent to 25 percent pushing gases to exit vents. This will avoid accumulation and levels will not exceed 10 ppm as described in studies of barn ventilation.

Prevent Stagnant Air Zones Where Odor Builds Up

Removal of stagnant pockets disperses odors of the manure and complaint is minimized by 20-30. Two HVLS fans can be used to keep the air fresh in a 20,000-square-foot barn to support the ceiling fans odor control barns.

Improve Overall Barn Ventilation and Air Exchange Rates

The fans augment air exchange by 10-20% which is in line with the ASABE (American Society of Agricultural and Biological Engineers) guidelines on livestock ventilation (0.1-0.2 cubic feet per minute/ pound of animal). This increases the amount of oxygen and minimizes the dangers of pathogens.

Reduce Condensation and Moisture, Limiting Bacterial Growth

HVLS fans reduce humidity by 10-15 percent due to evaporations, and these are preventing the growth of bacteria in wet regions. This minimises scours amongst calves by 15-20 according to research by animal health experts.

Benefits for Farmers

HVLS fans bring about a real benefit to farm activities and sustainability.

Improved Livestock Health and Performance

Reduced ammonia lowers the disease burden, as well as raises milk production by 5-15 percent and growth rates by 10 percent. Fan installation reduced the mortality at a dairy farm by 12% mortality.

Lower Veterinary Costs and Reduced Mortality

Fewer infections saved 2-5,000 dollars off the vet bills on 100 animals each year and mortality reduced by 5-10%.

Better Working Conditions and Compliance with Odor Regulations

Fans enhance comfort of workers, they minimize turnover and assist to meet EPA limits on emission thereby preventing fines and improving relationships with the community.

Case Example: A Dairy Barn’s Transformation

A 100 cow dairy barn in the Midwest experienced ammonia concentration of 30ppm, which led to respiratory problems and 15 percent milk production loss. Smell caused the complaint of the neighbors, which amounted to the fines. The installation of 3 HVLS fans 18 feet in diameter enhanced the ventilation of odor in the barn by reducing the ammonia levels to 10 ppm and by 25 percent the odor. The increase in milk output was 10 percent, reduction in mortality was 8 percent, and the decrease in vet expenditure was 3000. HVLS fans barn ventilation ROI in 18 months by saving the company 2,500 on energy every year.

FAQ: Common Questions About Ceiling Fans in Barns

- Do ceiling fans eliminate ammonia completely?

No, but they eliminate 15-25% of concentrations by dispersion; they work best with manure management. - Are fans enough or do they need to be paired with other systems?

Fans are good in air flow combined with the addition of exhaust vents or scrubbers in order to reduce ammonia livestock housing wholly. - Do HVLS fans increase dust circulation in barns?

No, when operating low speed the amount of dust disturbance is minimised and the quality of the air is better. - How do fans improve barn odor control?

Fans, when dispersed with volatile compounds, minimize odors by 20-30% to help with odor ventilation and compliance by the barracks.

Conclusion

In barns, the health risks, loss of productivity, and compliance problems are caused by ammonia and odors, which can be reduced successfully by the HVLS fans through the better airflow. Industrial ceiling fans should be used by farmers in their ventilation strategy to reduce ammonia and odor, as well as make the environment healthier. RTFANS is a 20+ years old company with custom HVLS solutions. Get in touch with us now to enhance the air quality of your barn- your animals and activities should have it.