The heat stress affecting workers in the manufacturing is an issue on the rise, and the OSHA and ISO impose tight standards regarding cooling the working environment in order to maintain the safety of the employees. Evaporative cooling can be considered an effective instrument in the attainment of factory cooling safety, OSHA compliance cooling, and the fresh filtered air, which can be brought to reduce heat stress at a cost that is compliant with the regulations. The article presents the manner in which evaporative cooling would guarantee adherence to heat-related standards in the workplace, reduce the threat of heat-related stress, and enhance worker health and productivity.

Workplace Heat Regulations in Manufacturing

The heat stress prevention rules by OSHA focus on the safe temperatures inside the facility and proper air circulation to avoid heat diseases among the people working in the manufacturing facilities. The General Duty Clause of the agency demands that employers should furnish a work-place without identified hazards such as excessive heat. The international standard of occupational health and safety ISO 45001 requires further having proper ventilation and temperature control in order to provide safety to the workers.

Failure to comply may result in the most serious consequences:

- Fines: The maximum OSHA fines on a heat-related violation may be more than 15,000 dollars per episode.

- Operational Disruption: Non-compliant facilities are prone to temporary closure.

- Liability and Morale: The inability to handle heat stress creates legal liability risks and reduces the morale of the employees and this affects retention.

Evaporative cooling is in line with these rules, and it is an inexpensive option to achieve the cooling safety qualifications in factories.

Heat Stress Risks in Factory Environments

The manufacturing plants are subjected to heat stress as a result of:

- Machinery Heat: Heavy equipment has large heat loads.

- Inadequate Ventilation: The spaces are large and closed to entrap air full of heat and stale air.

- Increased Intensity of Physical activity: The physical activity of workers increases the risks of heat exposure.

According to OSHA, thousands of cases of heat-related illnesses are registered every year with manufacturing taking a good proportionality. These will result in dehydration, exhaustion, low productivity as well as severe health hazards such as heat stroke. Proper cooling of work places and cooling of employee health is essential in preventing heat stress and cooling of employees.

Evaporative Cooling as a Compliance Tool

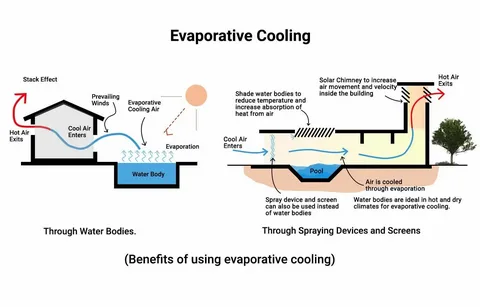

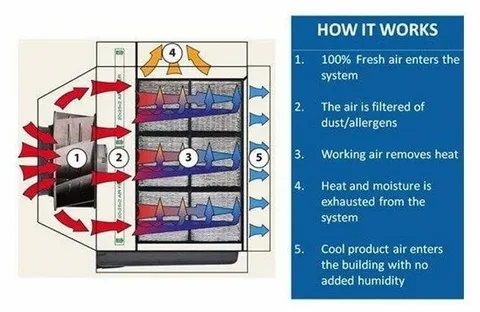

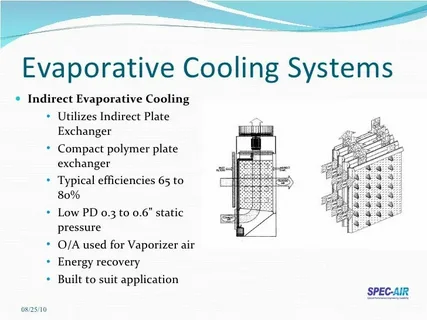

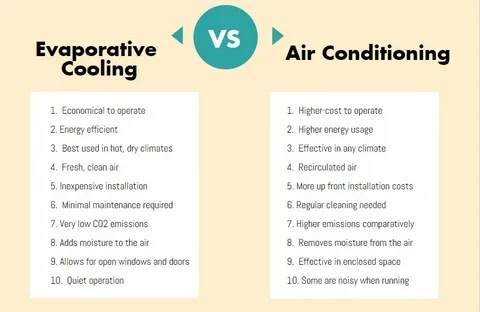

The evaporative coolers operate on the principle of receiving hot air through wet pads that are water soaked, and the air cools down naturally through evaporation. This mechanism provides clean filtered airflow as opposed to the traditional AC systems which recirculate air or fans which only circulate hot air.

How Evaporative Cooling Meets Regulatory Needs:

- Proper Air circulatory: There should be a sufficient amount of air flow in the workplace that serves to maintain a steady ventilation, which is required by OSHA on fresh air exchange.

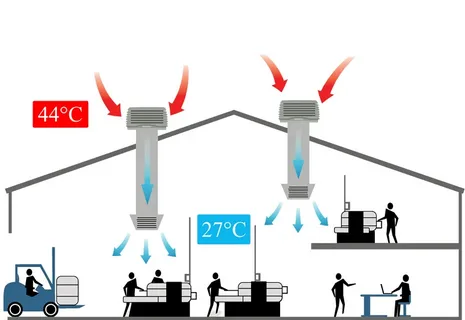

- Temperature Reduction: It decreases ambient temperatures by up to 20 o F in dry climates reducing heat stress.

- Better Air Quality: Dusts and pollutants are filtered to form a cleaner breathing environment that meets the requirements of the ISO 45001 standards.

Evaporative cooling is a convenient and cost-effective cooling mechanism in comparison to AC (high energy, complicated ducting) or fans (no cooling effect).

Creating Safer Work Environments

Worker Health & Productivity

The evaporative cooling technique helps a great deal in alleviating heat related illness by keeping the temperatures and air flowing. Research has revealed that lower temperatures in the workplace increase concentration and decrease the number of accidents by up to 15 percent and overall productivity. Employees have been noted to be more satisfied with their jobs and this has led to reduced turnover rates and enhanced safety culture.

Air Quality & Dust Control

Dust and particulates are filtered naturally by evaporative coolers when the air is moved through the pads moistened with water to enhance indoor air quality. This plays a vital role in a factory setting where the dust of such materials as metal or cloth may lead to respiratory problems. Healthier air is also in line with OSA ventilation requirements and promotes cooling of employees health.

Benefits for HR & Operations

Compliance Risk Reduction

Evaporative cooling will help factories to escape OSHA penalties and express their proactive concern about the safety of employees. ISO 45001 compliance also boosts the performance of auditing making facilities forefront of occupational health.

Lower Absenteeism & Insurance Costs

Healthier workplaces also result in a reduction in the number of sick days and some facilities have seen a 20 percent decline in the level of heat-related absenteeism since the introduction of evaporative cooling. Better safety records would also reduce the operation costs as it reduces the workers compensation insurance costs.

Employer Brand & Recruitment

Skilled talent in the competitive labor markets is available in safe, comfortable working environments. Evaporative cooling helps to achieve corporate social responsibility (CSR), environmental, social, and governance (ESG) objectives by focusing on the health and energy efficiency of the employees, as well as, improving the employer image.

Case Study & Example Scenarios

Electronics Manufacturing Facility

The evaporative coolers were installed in an electronic plant located in a warm climate in order to meet ISO 45001. The system lowered temperature indoors by 15 o F and negative complaints on heat discomfort by workers dropped by 25 percent. The ventilation also increased the quality of air, which is corresponding with the OSHA standards and productivity was increased by 10%.

Metal Fabrication Plant

An old-fashioned fans were substituted by evaporative coolers in a metal fabrication facility, and the cases of heat-related illness were reduced 30 percent. It was found that the enhanced air movement and temperature regulation kept the company in line with the OSHA heat stress regulations, with the workers claiming that they were more focused and had less fatigue-related mistakes.

These illustrations underscore the fact that evaporative cooling provides quantifiable safety and compliance advantages in the actual manufacturing environments.

Best Practices for Implementing Evaporative Cooling

To optimise the cooling safety and compliance of the factory:

- Strategic Positioning: To focus the problem areas, evaporative coolers should be installed in areas with high heat, e.g. machinery or assembly lines.

- Install Exhaust Fans: Use exhausts to match the pair of coolers to allow equal airflow through large areas.

- Routine Maintenance: Clean pads regularly and inspect water systems to ensure they perform and do not produce air of poor quality.

To learn more, see our blog article on Reducing Heat Stress to Workers in Factories or our Evaporative Air Coolers in Factory.

Conclusion

Evaporative cooling has been used as an effective solution towards OSHA compliance cooling and prevention of heat stress at workplaces in manufacturing. It provides cleaner, healthier air, cooler temperatures, and better quality of air, making work environments safer and more productive and complying with OSHA and ISO 45001 requirements. When investing in evaporative cooling, it involves investing in compliance, productivity, and people.

The industrial evaporative cooling systems of Discover KoolAir have been designed to be safe, compliant and well-being-oriented of workers. Ask the cooling plan to be compliance-ready.

FAQ

How do evaporative coolers help factories comply with OSHA standards?

Evaporative coolers offer good air circulation and clean and filtered air, which address the OSHA requirements to ventilation and the prevention of heat stress.

Can evaporative cooling reduce workplace heat stress illnesses?

Yes, evaporative coolers can significantly decrease heat-related illnesses by cooling the air (up to 20 o C) and increasing its flow.

Are evaporative coolers accepted in ISO safety audits?

Their ventilations and air quality improvement capacities comply with the ISO 45001 occupational health and safety standards, yes.