Industrial Air Cooler

Why Industrial Evaporative Air Cooler?

High indoor temperatures can cause low output, low livestock productivity, and employee dissatisfaction. It may increase the frequency of errors and accidents on your production and assembly line.

Industrial Evaporative Coolers can cool and humidify the air by evaporation evaporative cooling is an energy-efficient, and cost-saving solution. The principal places where they can cool down include warehouses, manufacturing plants, workshops, construction sites, and hangars, as well as stadiums, loading docks, marquee tents, garages, farms, sporting events, barns, swimming pools or terraces, etc.

What is an evaporative air cooler?

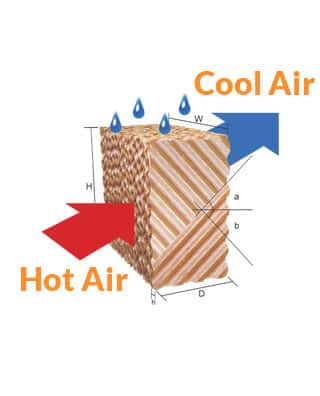

Evaporative cooling is a better way for nature to control the climate effectively. The physical body uses an equivalent cooling principle to chill the skin through the evaporation of water (sweat). Thanks to the low power consumption, it’s better to use evaporative cooling in an application environment that reduces heat while saving energy. The air passes through the cooling pad, and the water evaporates with the assistance of the power by air. Consequently, the air is cooled only by the fan and the pump. The Original air is exhausted and replaced with fresh cooling air.

It can provide a more efficient cooling and humidification effect and reliable service for several years consistently. High indoor temperatures can cause low output, low animal productivity, and employee dissatisfaction. Moreover, the too-high indoor temperature will increase the frequency of errors and accidents on your production and assembly line. In general, evaporative cooling is an efficient and energy-efficient, and cost-saving solution.

How does the industrial evaporative air cooler work?

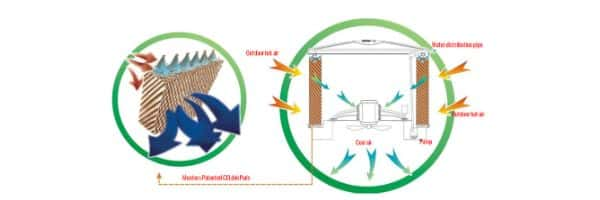

As schematically shown, when the cooler is working, water is pumped from the water tank to the water distributor, and distributed evenly to the evaporative cooling pads, then goes back to the tank. Meanwhile, the outside hot air is drawn through the wetted cooling pads and filtered and reduced in temperature before delivering to the userspace.

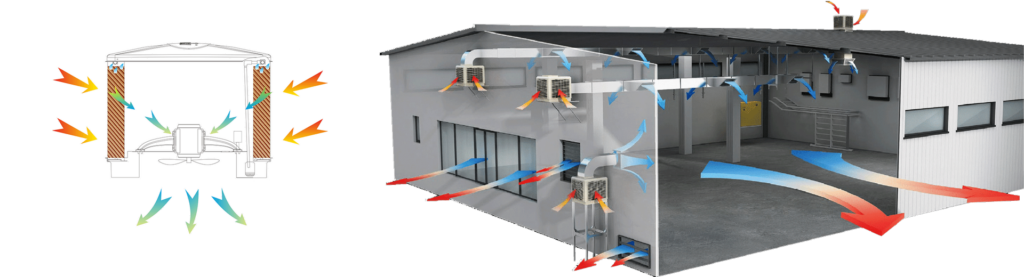

After being filtered and cooled by an evaporative air cooler, the outdoor fresh air is continuously sent into the indoor space through the air duct and air supply outlets. With the continuous supply of fresh air, the indoor space is in a positive pressure condition, thus the original hot air containing peculiar smell and dust will be emitted out of the room, resulting in a cool, ventilated, clean, and comfortable environment. Proper exhaust area and effective exhaust are essential for the satisfactory performance of any evaporative air cooling system.

RTFANS Innovation Standard