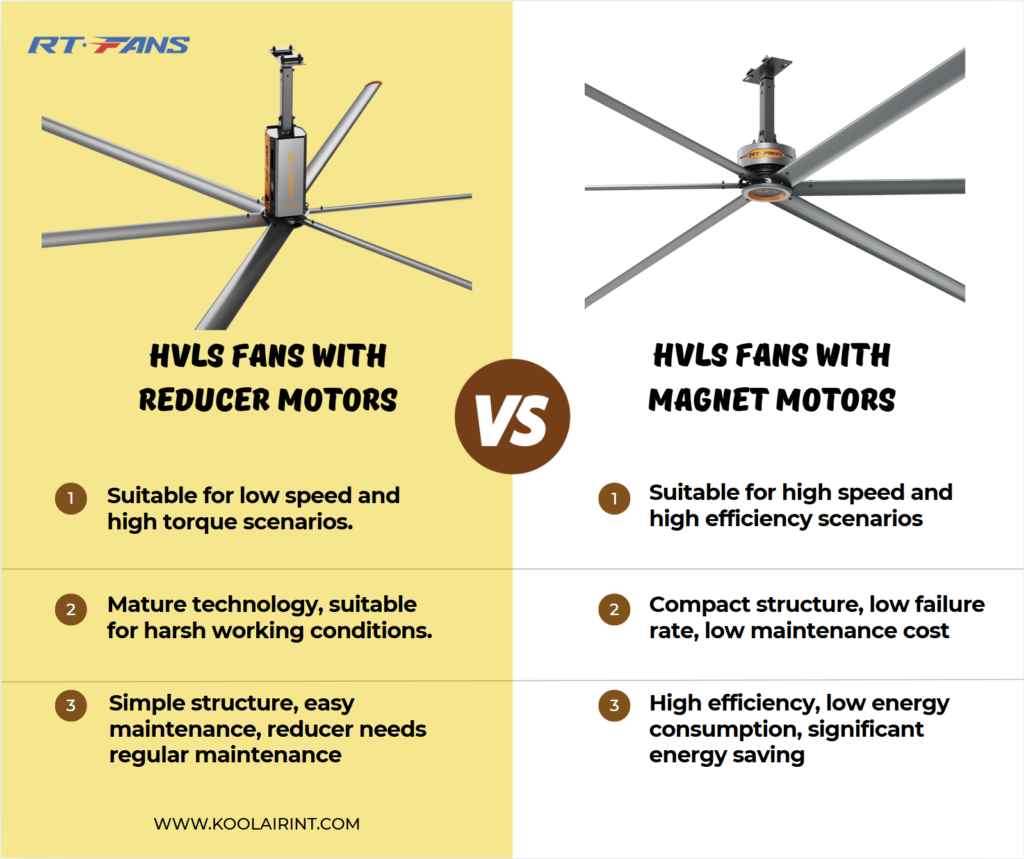

In daily communication, customers usually don’t know whether to choose an industrial hvls fan with a reducer motor or a permanent magnet motor, and often need us to make recommendations. To recommend a suitable product, you need to first understand the advantages and disadvantages of the two motors. The following is a comprehensive comparison of RTFANS industrial hvls fan with reducer motor and fan with permanent magnet inner rotor motor:

Efficiency and energy consumption

Industrial hvls fans with reducer motors:

- Advantages: Mature technology, suitable for high-power, low-speed applications, and the reducer can adjust the output speed.

- Disadvantages: Large mechanical transmission loss, low overall efficiency, and higher energy consumption compare to magnet motor.

Fans with permanent magnet inner rotor motors:

- Advantages: Permanent magnet motors have high efficiency, low energy consumption, significant energy-saving effects, and are suitable for high-speed applications.

- Disadvantages: High initial cost.

________________________________________

Structure and maintenance

Industrial hvls fans with reducer motors:

- Advantages: Simple structure, easy maintenance, mature reducer technology, and low maintenance costs.

- Disadvantages: The reducer requires regular maintenance (such as lubrication, gear replacement, etc.), which increases the maintenance workload. (RTFANS provide 20000 running hours’ free maintenance assurance)

Fans with permanent magnet inner rotor motors:

- Advantages: compact structure, no mechanical transmission parts, low maintenance cost, and low failure rate.

- Disadvantages: Once the permanent magnet motor is damaged, it is difficult to repair and the entire motor may need to be replaced.

________________________________________

Noise level

Fans with traditional reducer motors:

- Advantages: no significant advantages.

- Disadvantages: Mechanical noise is generated during the operation of the reducer, and the overall noise level is higher than magnet motor fan.

Fans with permanent magnet inner rotor motors:

- Advantages: low noise during operation, providing a quieter working environment.(magnet noise is still there especially at certain frequency)

- Disadvantages: no significant disadvantages.

________________________________________

Adaptability and reliability

Fans with traditional reducer motors:

- Advantages: mature technology, high reliability, suitable for harsh working conditions (such as high temperature, high humidity, and dusty environments).

- Disadvantages: The reducer may require more frequent maintenance in harsh environments.

Fans with permanent magnet inner rotor motors:

- Advantages: Strong adaptability, suitable for a variety of working conditions, especially high speed and high efficiency demand scenarios.

- Disadvantages: Permanent magnet materials may demagnetize in high temperature environments, affecting performance.

________________________________________

Cost and cost performance

Fans with traditional motors with reducers:

- Advantages: Low initial cost, suitable for customers with limited budgets.

- Disadvantages: Higher energy consumption in long-term operation, high maintenance cost, and average overall cost performance.

Fans with permanent magnet inner rotor motors:

- Advantages: Low energy consumption in long-term operation, low maintenance cost, and high overall cost performance.

- Disadvantages: High initial cost and if motor damaged it cannot be repaired.

Technical features

Fans with traditional motors with reducers:

- Advantages: Mature technology, wide market application, suitable for low speed and high torque scenarios.

- Disadvantages: Low mechanical transmission efficiency and slow response speed.

Fans with permanent magnet inner rotor motors:

- Advantages: fast response speed, high control accuracy, suitable for high speed and high efficiency scenarios.

- Disadvantages: The technology is relatively new, and some customers may have doubts about its long-term reliability.

RTFANS industrial hvls fan with reducer motor has mature technology and is suitable for low-speed, high-torque scenarios, especially for spaces above 8 meters (up to 40 meters). The initial cost is low, but the long-term operating energy consumption and maintenance costs are higher than permanent magnet motor fans (RTFANS configuration can reach 20,000 hours maintenance-free). The RTFANS permanent magnet inner rotor motor has high efficiency, low energy consumption, low noise, and low maintenance cost. It is suitable for high-speed, high-efficiency demand scenarios and is recommended for 6-15 meters. Although the initial cost is high, the long-term cost-effectiveness is higher. According to your specific needs (such as working conditions, budget, efficiency requirements, etc.), we can recommend the most suitable fan solution for you.