How to position an industrial HVLS fan before installation? Location is important for the installation of HVLS (High volume low speed) fans. Placing the right fan at the right place and height can not only ensure the maximum air volume (meaning the same money but the best effect) but also ensure that no matter what season, they can provide a comfortable working environment.

Industrial HVLS Fans differ from traditional fans. They are energy-saving and eco-friendly while ventilating and cooling. They play an increasingly irreplaceable role in the ventilation and cooling of tall and large spaces.

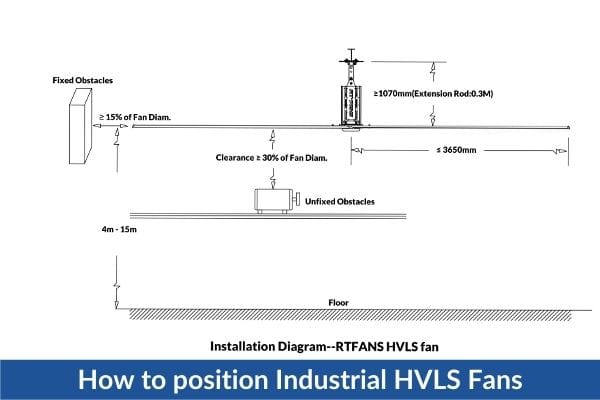

As shown in the above picture, the airflow of the HVLS fan moves freely from the ceiling to the floor and then moves outward in all directions. Therefore, we should install the HVLS Fan in we should not place as open a place as possible and close to walls or other obstacles, because this may increase air resistance and reduce airflow, reducing the effective coverage area. Ideally, the height of the industrial HVLS fan (with a diameter of 24ft, 7.3m) from the ground is between 7-9 meters (we usually use an extension rod to adjust the height of the fan to achieve the best). Facilities with very high ceilings will require multiple fans to be spaced closer together to provide adequate airflow on the working floor.

How to position industrial HVLS fans and decide the number of fans in installation? It is reasonable to keep the space between 15 meters and 25 meters for each two industrial HVLS fans. In such an area, it can achieve an ideal ventilation and cooling effect.

The ventilation and cooling effect of industrial HVLS fans mainly depends on the following three facts.

1. Space above the HVLS Fan

The gas storage area is the distance between the fan blade level and the roof-this area. According to related calculations, the optimal height of the gas storage area is over 1 meter. industrial HVLS fan can produce a tremendous amount of air- about 13,000 cubic meters per minute. If the height does not reach the ideal state because of the traveling crane or roof height restrictions, it will reduce the air volume per minute because of insufficient gas storage area volume. Here, we should increase the density of fans.

2. Space BELOW the HVLS Fan

The height of the fan blades level from the ground. This height determines the coverage of the wind. When the height of the fan blades level from the ground is lower than 6 meters, the wind pressure is stronger, but the coverage area is small. Therefore, if the height of the fan blades level from the ground is lower than 6 meters, it should appropriately increase the fans density according to actual needs to get a relatively perfect coverage; the best installation height of the HVLS Fans is that the fan blades level is 7-9 meters away from the ground, in this range, the air volume, coverage, and comfort can achieve the best effect; When the height is 9-13 meters, the wind pressure is slightly lower, and it has no obvious effect on the ventilation and cooling effect. But when the fan blade level is 14 meters or more above the ground, it will significantly reduce the effect. Try to avoid the fan blade level at this height.

3. The Structure of the HVLS fan Coverage Area

The ground layout and structure. If the structure is very complex, for example, there is more ground equipment and partitions, it will obstruct the air circulation to a certain extent and affect the ventilation effect. Here, we should increase the fan density according to the actual situation.

Then how do install the HVLS fans? The installation of industrial HVLS fans is particularly important because we suspended them on the roof. Correct installation can not only ensure that the failure rate of industrial HVLS fans is reduced, but the most important thing is to ensure the safety and stability of users. Industrial HVLS fans with a blade diameter of up to 7.3 meters have the lightest weight of over 100 kilograms. If it falls from a height of a few meters or even more than a dozen meters, it will be a big problem. So how do install the HVLS industrial fans properly? What are the correct installation methods and steps?

- Check the parts, shapes, and dimensions related to assembly, and confirm the parts list and technical description before starting assembly. If it damaged the surface of the parts before assembly, it requires repair or replacement;

- There are strict installation requirements to follow. Make sure you read the instruction manual and follow the steps and tips during assembly and installation.

- The installation of industrial HVLS fans must follow the drawings;

- Ensure that all fasteners are firm and fixed;

- We install industrial-grade HVLS fans, according to the technical requirements you need to check the accessories are installed correctly, ensure debugging under conditions of safety and operation;

- Avoid installing fans under any lighting fixtures. This will prevent the “stroboscopic effect” when the fan is running. The fan blade clearance is very important! Hanging the fan too close to potential obstacles can cause safety hazards. RTFANS’ recommendation: Keep fan blades from unfixed obstacles (eg. Industrial Chandelier) at a minimum 30% distance of the fan diameter. Keep fan blades from fixed obstacles (e.g. wall or crane structure) at a distance of a minimum of 15% of the fan diameter.